Palm oil refining process machinery

The Crude Palm Oil Extracted from the palm oil press machine and palm oil mill plant contains the unwanted impurities which effect adversely on the physical appearance, quality, oxidative stability, shelf life of the oil. In order to remove the above impurities, the oil goes to the palm oil refining process machinery in order to receive the RBD (Refined Bleached & Deodorized) Palm Oil . After refining of the palm oil the RBD oil goes to the fractionation section in order to get the palm olein and palm stearin.

Continuous palm oil refinery plant (with capacity 50-1000tpd)

Refining is the process in which we remove the undesirable impurities from Crude Palm oil as mentioned below.

Phospholipids

Free fatty acid

Coloring pigments (Carotenoids).

Moisture, oxidative material, metal impurities, and water soluble impurities (glycerol, Phenols, Sugars).

(The palm oil refining includes the removal of above impurities in order of increasing shelf life and quality of Refined Vegetable oil.)

Henan Doing Company is a leading turnkey project supplier and manufacture of Palm oil refining process machinery from China. we can supply 1-10tpd small scale palm oil refinery plant, Continuous palm oil refinery plant, Palm oil fractionation plant, 2tpd palm kernel oil refinery plant, 50tpd continuous palm kernel oil refinery plant and so on.

Palm oil refining process consists of the following sections:

Degumming process

Bleaching process

Deodorisation / De-acidification

Palm oil refining process flow chart:

Palm oil refining process flow chart

Palm oil degumming process: Degumming process is the first refining process of edible oil refinery.For palm oil refining process, we mainly adopts dry degumming process of palm oil.Technically, degumming of palm oil is referred as an operation of purification in palm oil refining process, since crude palm oil (CPO) normally contains impurities in the colloidal state or dissolved in them. In degumming process, phospholipids featured of strong emulsifying action are removed by a variety of treatments. In short, degumming of palm oil is a process of removing unwanted gums, so that to ensure the stability of the palm oil in later stage of refining plant.

Palm oil bleaching process / palm oil decolorization process: During palm oil bleaching stage, trace metal complexes such as iron and copper, coloring pigments, phosphatides and oxidative products are removed by adsorptive effect of bleaching earth.

This bleached oil is then filtered in industrial filters such as filter press or hermetically sealed vertical leaf pressure filter, plate and frame type filter.

Deodorization / De-acidification is done to to remove residual pigments, and oxidation products etc, which would otherwise adversely affect the flavour, odour and rate at which the oil would turn rancid. In Deodorization process, free fatty acid removes in the form of Palm fatty acid distillate as a refining waste.

Apart from removal of free fatty acid there are some impurities like Carotenoids pigments, primary and secondary oxidation products present in the palm oil are also removed from refined Palm oil in this step. Deodorization is essentially a steam distillation process carried out at low pressures and elevated temperatures (180-220°C).

Palm oil refining process machinery photos:

Continuous palm oil refining process machinery

After palm oil refining process, we can get RBD Palm Oil, if we want get palm olein and palm stearin, we need to sent RBD Palm Oil to palm oil fractionation plant for further processing.

New palm oil fractionation technology adopts advanced crystallization equipment, filtration & pressing technology, and accurate temperature auto-control software, which keep paces with the word. The new technology is especially applicable for the palm oil fractionation, which can get different melting-point fractionations, including 14℃, 18℃, 24℃, 32℃ etc. Meanwhile, we can control and change the filtration mode by regulating crystallization rate, crystallization temperature and maturing time. The above technology is suitable for the fractionation of to palm oil, palm kernel oil etc. Thus raising the added value and increasing enterprise economic benefit.

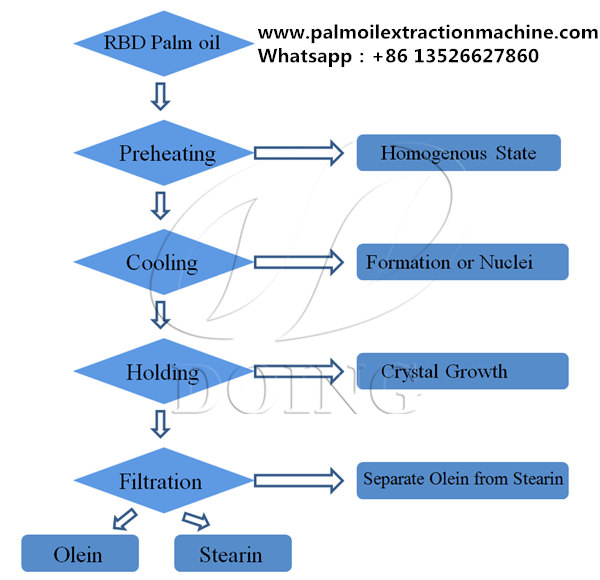

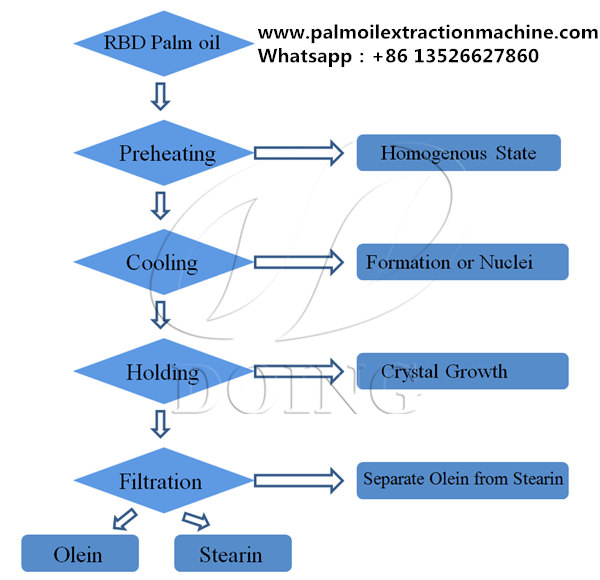

Palm oil fractionation process flow chart as follows:

Palm oil refinery process flow chart

Contact us to get more information on palm oil refining process, palm oil fractionation process and related machine to double your palm oil mill output. Henan Doing Company always at your service.Our palm oil refining machine business scope as follows:

1-10tpd batch type palm oil refining machine;

10-30tpd semi-continuous palm oil refining machine;

30-1000tpd continuous palm oil refining machine;

Continuous palm oil refinery plant (with capacity 50-1000tpd)

Phospholipids

Free fatty acid

Coloring pigments (Carotenoids).

Moisture, oxidative material, metal impurities, and water soluble impurities (glycerol, Phenols, Sugars).

(The palm oil refining includes the removal of above impurities in order of increasing shelf life and quality of Refined Vegetable oil.)

Henan Doing Company is a leading turnkey project supplier and manufacture of Palm oil refining process machinery from China. we can supply 1-10tpd small scale palm oil refinery plant, Continuous palm oil refinery plant, Palm oil fractionation plant, 2tpd palm kernel oil refinery plant, 50tpd continuous palm kernel oil refinery plant and so on.

Palm oil refining process consists of the following sections:

Degumming process

Bleaching process

Deodorisation / De-acidification

Palm oil refining process flow chart:

Palm oil refining process flow chart

Palm oil refining process machinery introduction:

Generally, palm oil refining process is necessary steps for the production of palm oil products. The qualities of the finished product that need to be monitored are flavor, shelf-life, stability and color of the products.Palm oil degumming process: Degumming process is the first refining process of edible oil refinery.For palm oil refining process, we mainly adopts dry degumming process of palm oil.Technically, degumming of palm oil is referred as an operation of purification in palm oil refining process, since crude palm oil (CPO) normally contains impurities in the colloidal state or dissolved in them. In degumming process, phospholipids featured of strong emulsifying action are removed by a variety of treatments. In short, degumming of palm oil is a process of removing unwanted gums, so that to ensure the stability of the palm oil in later stage of refining plant.

Palm oil bleaching process / palm oil decolorization process: During palm oil bleaching stage, trace metal complexes such as iron and copper, coloring pigments, phosphatides and oxidative products are removed by adsorptive effect of bleaching earth.

This bleached oil is then filtered in industrial filters such as filter press or hermetically sealed vertical leaf pressure filter, plate and frame type filter.

Deodorization / De-acidification is done to to remove residual pigments, and oxidation products etc, which would otherwise adversely affect the flavour, odour and rate at which the oil would turn rancid. In Deodorization process, free fatty acid removes in the form of Palm fatty acid distillate as a refining waste.

Apart from removal of free fatty acid there are some impurities like Carotenoids pigments, primary and secondary oxidation products present in the palm oil are also removed from refined Palm oil in this step. Deodorization is essentially a steam distillation process carried out at low pressures and elevated temperatures (180-220°C).

Palm oil refining process machinery photos:

Continuous palm oil refining process machinery

After palm oil refining process, we can get RBD Palm Oil, if we want get palm olein and palm stearin, we need to sent RBD Palm Oil to palm oil fractionation plant for further processing.

New palm oil fractionation technology adopts advanced crystallization equipment, filtration & pressing technology, and accurate temperature auto-control software, which keep paces with the word. The new technology is especially applicable for the palm oil fractionation, which can get different melting-point fractionations, including 14℃, 18℃, 24℃, 32℃ etc. Meanwhile, we can control and change the filtration mode by regulating crystallization rate, crystallization temperature and maturing time. The above technology is suitable for the fractionation of to palm oil, palm kernel oil etc. Thus raising the added value and increasing enterprise economic benefit.

Palm oil fractionation process flow chart as follows:

Palm oil refinery process flow chart

Contact us to get more information on palm oil refining process, palm oil fractionation process and related machine to double your palm oil mill output. Henan Doing Company always at your service.Our palm oil refining machine business scope as follows:

1-10tpd batch type palm oil refining machine;

10-30tpd semi-continuous palm oil refining machine;

30-1000tpd continuous palm oil refining machine;

Call us

Call us Chat online

Chat online