1-10tpd small scale palm oil refinery plant

1-10tpd small scale palm oil refinery plant belongs to batch type palm oil refinery plant. Small scale palm oil refinery plant is the best choice for small capacity palm oil mill. The small scale palm oil refinery plant can efficiently remove phospholipids, FFA, pigment, gums, waxes, off-flavor and other impurities.

Our small scale palm oil refinery plant is widely used in cooking oil refining process, such as peanut oil refining process, soybean oil refining process, cottonseed oil refining process, rice bran oil refining process, palm oil refining process , palm kernel oil refining process, etc.

Some reference information 1-10tpd small scale palm oil refinery plant:

Product name : Batch type palm oil refinery plant

Capacity: 1-10tpd

Refining process: degumming process+ deacidification process + decolorization process+ deodorization process

Application : corn germ oil, soybean oil, peanut oil, sunflower oil, cototnseed oil, rice bran oil, plam oil, palm kernel oil and so on.

Operating workers: 5-7persons

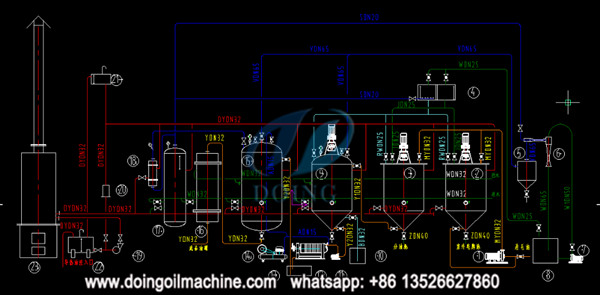

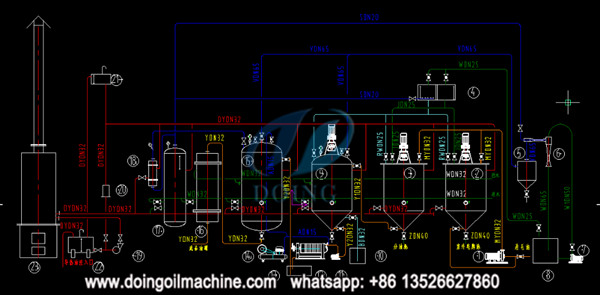

1-10tpd small scale palm oil refinery plant process flow chart:

Small scale palm oil refinery plant process flow chart

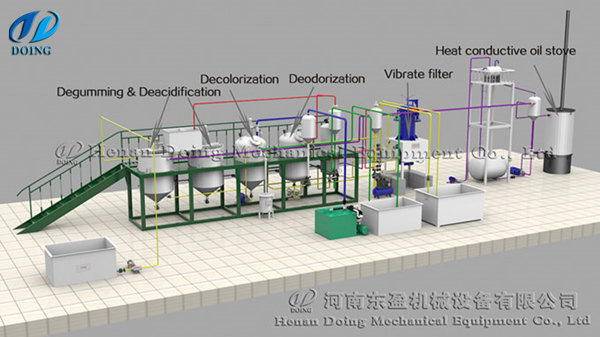

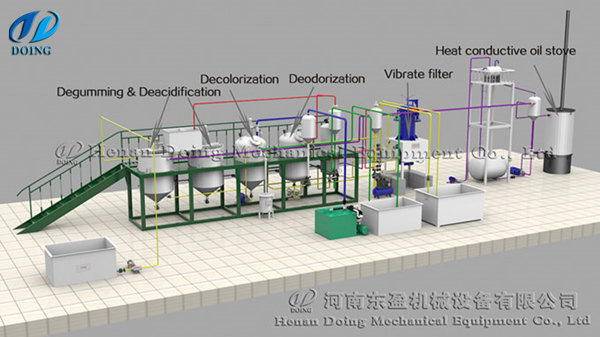

Main equipment in 1-10tpd small scale palm oil refinery plant:

Refining pot: to remove gum and impurities from crude oil, and using alkali to neutralize acid inside crude oil

Decolorization pot: To move the pigment in the oil.

Deodorization pot: To move the bad smells in the cooking oil.

Conductive oil stove: It is used to provide the heat for the whole batch type cooking oil refinery plant process.

Vacuum pump: The function of batch type cooking oil refinery plant is to provide vacuum for decolorization and deodorization.

Air compressor: It will dry the white clay after absorb the pigment in the oil.

Steam generator: To generate the steam for the deodorization pot.

1-10tpd small scale palm oil refinery plant

Featured advantages of 1-10tpd small scale palm oil refinery plant:

(1)Suitable for small capacity like 1-2-3-5-10TPD

(2)20 years manufacturing, sales and installation experience on palm oil refinery project.

(3)Excellent technical and economical indicators

(4)Meeting customers’ different palm oil refining requirements at home and abroad

(5)The whole line of small scale palm oil refinery plant including degumming, de-acidification, de-colorization, deodorization.

Photos show of different capacity palm oil refinery plant :

The above picture whow us the different capacity palm oil refinery plant designed by Henan Doing Company

We have been specialized in palm oil refinery plant for decades. Our professional engineers can help you design and install palm oil refinery plant according to your capacity and requirements. If you are interested in small scale palm oil refinery plant, please feel free to contact us. Besides palm oil refinery plant ,we can also offer as follows:

Palm fruit /palm kernel pressing line:

1-2-3-5TPH small palm oil processing plant;

15-30-45-60-80-120TPH palm oil processing plant;

5-600TPD palm kernel oil processing plant;

Palm oil refining:

1-2-3-5-10TPD batch palm oil refinery plant;

10-15-20-25-30-50TPD semi continuous palm oil refinery plant;

50-80-100-150-300-600TPD full continuous palm oil refinery plant;

Our small scale palm oil refinery plant is widely used in cooking oil refining process, such as peanut oil refining process, soybean oil refining process, cottonseed oil refining process, rice bran oil refining process, palm oil refining process , palm kernel oil refining process, etc.

Some reference information 1-10tpd small scale palm oil refinery plant:

Product name : Batch type palm oil refinery plant

Capacity: 1-10tpd

Refining process: degumming process+ deacidification process + decolorization process+ deodorization process

Application : corn germ oil, soybean oil, peanut oil, sunflower oil, cototnseed oil, rice bran oil, plam oil, palm kernel oil and so on.

Operating workers: 5-7persons

1-10tpd small scale palm oil refinery plant process flow chart:

Small scale palm oil refinery plant process flow chart

Main equipment in 1-10tpd small scale palm oil refinery plant:

Refining pot: to remove gum and impurities from crude oil, and using alkali to neutralize acid inside crude oil

Decolorization pot: To move the pigment in the oil.

Deodorization pot: To move the bad smells in the cooking oil.

Conductive oil stove: It is used to provide the heat for the whole batch type cooking oil refinery plant process.

Vacuum pump: The function of batch type cooking oil refinery plant is to provide vacuum for decolorization and deodorization.

Air compressor: It will dry the white clay after absorb the pigment in the oil.

Steam generator: To generate the steam for the deodorization pot.

1-10tpd small scale palm oil refinery plant

Featured advantages of 1-10tpd small scale palm oil refinery plant:

(1)Suitable for small capacity like 1-2-3-5-10TPD

(2)20 years manufacturing, sales and installation experience on palm oil refinery project.

(3)Excellent technical and economical indicators

(4)Meeting customers’ different palm oil refining requirements at home and abroad

(5)The whole line of small scale palm oil refinery plant including degumming, de-acidification, de-colorization, deodorization.

Photos show of different capacity palm oil refinery plant :

The above picture whow us the different capacity palm oil refinery plant designed by Henan Doing Company

Palm fruit /palm kernel pressing line:

1-2-3-5TPH small palm oil processing plant;

15-30-45-60-80-120TPH palm oil processing plant;

5-600TPD palm kernel oil processing plant;

Palm oil refining:

1-2-3-5-10TPD batch palm oil refinery plant;

10-15-20-25-30-50TPD semi continuous palm oil refinery plant;

50-80-100-150-300-600TPD full continuous palm oil refinery plant;

prev: Continuous palm oil refinery plant

Next: Nothing

Call us

Call us Chat online

Chat online