2tpd palm kernel oil refinery plant

Palm kernel oil refining process is similar with palm oil refining process which also takes place in four stages. These stages of palm kernel oil refining process include degumming & deacidification process, bleaching process, and deodorization process. This 2tpd palm kernel oil refinery plant belongs to batch type palm kernel oil refinery plant. In order to get better qualified oil , palm kernel oil refinery plant is needed in palm kernel oil production process . Henan Doing Company is a professional supplier of palm kernel oil refinery plant in China. We offer the best machinery with the most competitive price to the customer all over the world. Join us and have your own palm kernel oil refinery plant .

Application of 2tpd palm kernel oil refinery plant:

2tpd palm kernel oil refinery plant is widely used in various kinds of edible oil, such as soybean oil, mustard seed oil, cottonseed oil, sunflower seed oil, peanut oil, rice bran oil, safflower seed oil, corn germ oil, camellia seed oil, palm oil, palm kernel oil and so on.

2tpd palm kernel oil refinery plant can process the above oilseeds

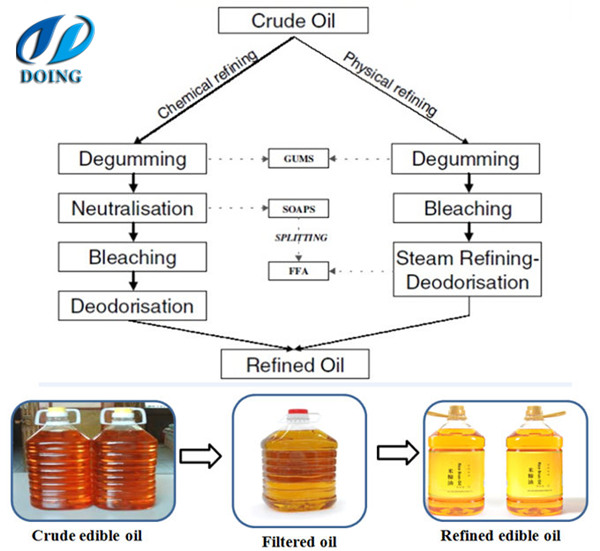

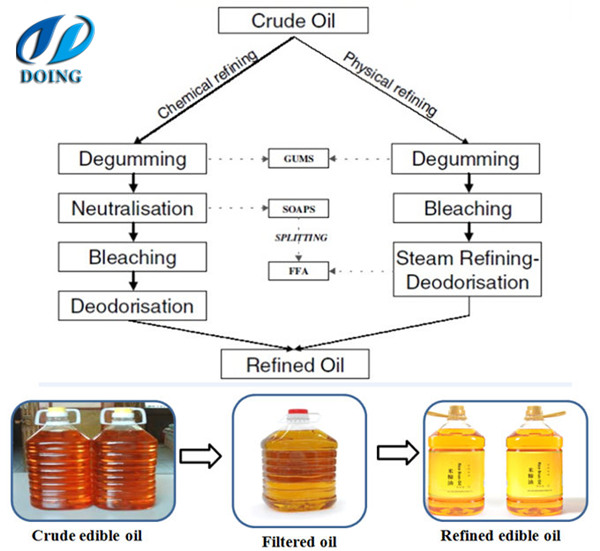

2tpd palm kernel oil refinery process flow chart:

Palm kernel oil refinery process flow chart

Detail introduction of 2tpd palm kernel oil refinery plant:

The first and key stage of the palm kernel oil refinery process is the de-gumming stage. The equipment used in this stage is the de-gumming tank. Palm kernel oil degumming process aims to removing the gum impurities in the crude oil to make it suitable for further refinery process, hydration degumming and special acid degumming are the two main methods.

The second stage of palm kernel oil refinery process is the neutralization process, which is also known as the de-acidification process. In this step free fatty acids are neutralized by using sodium hydroxide and convert them into soap. Additional impurities are also removed by adsorption on soap.

The third stage of palm kernel oil refinery process is the bleaching process(also named decolorization process). This process’s main purpose is to remove the product of oxidation, pigments, phospholipids, soap materials from the oil. This palm kernel oil decolorization process can improve the oil color as well as supplies high quality oil for the deodorization process.

The fourth stage is palm kernel oil deodorization process. Deodorization machine is used to remove unacceptable odors by steam distillation during soybean oil refinery plant, the odoriferous compound are stripped off with the help of live injected steam into heated oil under high vacuum pressure.

2tpd palm kernel oil refinery plant photos show:

Details pictures of 2tpd palm kernel oil refinery plant

Considering the need of palm kernel refinery plant and the customs' requirement, we selects best technology and superior equipment fabrication and automatic control system, which provides perfect technique and service to satisfy the customs' refining requirement and to create first-class refining process with our professional palm kernel refinery plant. Any one who need palm kernel oil refinery plant can contact us.

Application of 2tpd palm kernel oil refinery plant:

2tpd palm kernel oil refinery plant is widely used in various kinds of edible oil, such as soybean oil, mustard seed oil, cottonseed oil, sunflower seed oil, peanut oil, rice bran oil, safflower seed oil, corn germ oil, camellia seed oil, palm oil, palm kernel oil and so on.

2tpd palm kernel oil refinery plant can process the above oilseeds

Palm kernel oil refinery process flow chart

The first and key stage of the palm kernel oil refinery process is the de-gumming stage. The equipment used in this stage is the de-gumming tank. Palm kernel oil degumming process aims to removing the gum impurities in the crude oil to make it suitable for further refinery process, hydration degumming and special acid degumming are the two main methods.

The second stage of palm kernel oil refinery process is the neutralization process, which is also known as the de-acidification process. In this step free fatty acids are neutralized by using sodium hydroxide and convert them into soap. Additional impurities are also removed by adsorption on soap.

The third stage of palm kernel oil refinery process is the bleaching process(also named decolorization process). This process’s main purpose is to remove the product of oxidation, pigments, phospholipids, soap materials from the oil. This palm kernel oil decolorization process can improve the oil color as well as supplies high quality oil for the deodorization process.

The fourth stage is palm kernel oil deodorization process. Deodorization machine is used to remove unacceptable odors by steam distillation during soybean oil refinery plant, the odoriferous compound are stripped off with the help of live injected steam into heated oil under high vacuum pressure.

2tpd palm kernel oil refinery plant photos show:

Details pictures of 2tpd palm kernel oil refinery plant

Considering the need of palm kernel refinery plant and the customs' requirement, we selects best technology and superior equipment fabrication and automatic control system, which provides perfect technique and service to satisfy the customs' refining requirement and to create first-class refining process with our professional palm kernel refinery plant. Any one who need palm kernel oil refinery plant can contact us.

Call us

Call us Chat online

Chat online