50tpd continuous palm kernel oil refinery plant

In order to get better palm kernel oil , palm kernel oil refinery plant is needed in palm kernel oil production process. Doing Group is a professional supplier of palm kernel oil refinery plant in China. We offer the best machinery with the most competitive price to the customer all over the world. We can customized batch type palm kernel oil refinery plant and continuous palm kernel oil refinery plant according to the customer's requirements.

Why palm kernel oil need to be refined?

After palm kernel oil extraction process, there are many impurities in the crude palm kernel oil, which might have bad influence on the oil’s sensory and edible qualities. Therefore, it is necessary to refine the crude palm kernel oil. In another word, without palm kernel oil refinery plant, the crude palm kernel oil is not edible for human being.

Palm kernel oil refinery plant 3D animation

Specification of 50tpd continuous palm kernel oil refinery plant:

(1) Purpose : Oil refining is according to the different usage and requirements , utilizing the physical methods and chemical processes to get rid of the harmful impurities and needless substance in the crude oil , getting some standard oil. Our palm kernel oil refinery plant is suitable for refining various crude vegetable oil, such as sunflower seed oil, tea seed oil, groundnut oil, cottonseed oil, palm oil, rice bran oil, soybean oil, corn oil and palm oil, etc.

(2)main parts: Crude oil filter, Crude oil tank, Crude oil pump, Washing centrifuge,Degumming centrifuge,Vacuum dryer, Hot water tank,Soap-stock tank,Decolorization tower,Decolorization oil pump,Plate filter, Steam super-heater,Decolorizing oil tank, Deodorization tower,Deodorization oil pump,Vacuum system, Vacuum pump, Cooling tower, Thermal oil furnace, PLC automatic control

(3) Advantage: a.After refining the impurity of oil must be less than 0.2% ;

b.Recycling system save power and money ;

c.Lower oil waste.

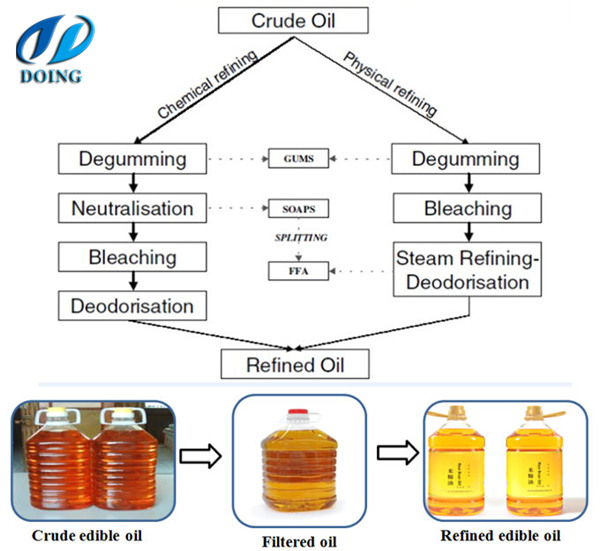

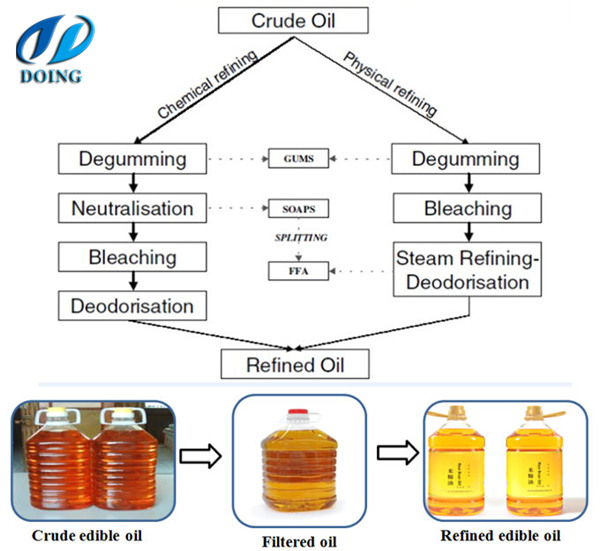

Process flow chart of 50tpd continuous pam kernel oil refinery plant:

Palm kernel oil refinery process flow chart

Main process of continuous palm kernel oil refinery plant:

Degumming process:

This is the first step in continuous palm kernel oil refinery plant and is also known as the Pretreatment Process. In the degumming process, the gums are precipitated and separated by the centrifugal separation technique. If the gum content in the oil is low, only gum-conditioning is required to be done and there is no need to go for separate degumming process. The degumming can be carried out in the same neutralization vessel.

Neutralizing process:

Every cooking oil consists certain amounts of free-fatty acids FFA's that increase the rancidity in oil and is harmful for human consumption. In neutralization, the FFA's are removed by reacting them with caustic soda- NaOH in the neutralizer at a certain temperature and performing the stirring. In this way, FFA gets separated in the form of soap stock. Henan Doing Company offers neutralization units.

Bleaching Process:

The color pigments in the oil are removed in the bleaching process of continuous palm kernel oil refinery plant. The neutralized oil is treated with certain chemicals like activated earth which removes the color from the cooking oil. This process is also carried out under temperature. The bleached oil is then filtered so that the added chemicals and particles are separated from the oil.

Deodorizing Process:

The deodorization is an important process in the continuous palm kernel oil refinery plant. This process is used to remove the odor from the oil. Every oil contains certain typical natural color.

During the previous processes, certain unwanted odor is applied on the oils. The deodorization process removes this odiferous material. It is carried out under high temperature and vacuum systems. At the completion of the process, we get the deodorized-odorless cooking oil.

Photos of 50tpd palm kernel oil refinery plant :

Continuous palm kernel oil refinery plant

Henan Doing Company is a leading designer, manufacturer and exporter of palm kernel oil refinery plant, We can supply batch type palm kernel oil refinery plant and continuous palm kernel oil refinery plant. Our continuous palm kernel oil refinery plant gives color uniformity and appealing quality to the oil by removing unpleasant smell and undesirable factors from the oil. If you are interested in palm kernel oil refinery plant, please contact us !

Why palm kernel oil need to be refined?

After palm kernel oil extraction process, there are many impurities in the crude palm kernel oil, which might have bad influence on the oil’s sensory and edible qualities. Therefore, it is necessary to refine the crude palm kernel oil. In another word, without palm kernel oil refinery plant, the crude palm kernel oil is not edible for human being.

Palm kernel oil refinery plant 3D animation

Specification of 50tpd continuous palm kernel oil refinery plant:

(1) Purpose : Oil refining is according to the different usage and requirements , utilizing the physical methods and chemical processes to get rid of the harmful impurities and needless substance in the crude oil , getting some standard oil. Our palm kernel oil refinery plant is suitable for refining various crude vegetable oil, such as sunflower seed oil, tea seed oil, groundnut oil, cottonseed oil, palm oil, rice bran oil, soybean oil, corn oil and palm oil, etc.

(2)main parts: Crude oil filter, Crude oil tank, Crude oil pump, Washing centrifuge,Degumming centrifuge,Vacuum dryer, Hot water tank,Soap-stock tank,Decolorization tower,Decolorization oil pump,Plate filter, Steam super-heater,Decolorizing oil tank, Deodorization tower,Deodorization oil pump,Vacuum system, Vacuum pump, Cooling tower, Thermal oil furnace, PLC automatic control

(3) Advantage: a.After refining the impurity of oil must be less than 0.2% ;

b.Recycling system save power and money ;

c.Lower oil waste.

Process flow chart of 50tpd continuous pam kernel oil refinery plant:

Palm kernel oil refinery process flow chart

Main process of continuous palm kernel oil refinery plant:

Degumming process:

This is the first step in continuous palm kernel oil refinery plant and is also known as the Pretreatment Process. In the degumming process, the gums are precipitated and separated by the centrifugal separation technique. If the gum content in the oil is low, only gum-conditioning is required to be done and there is no need to go for separate degumming process. The degumming can be carried out in the same neutralization vessel.

Neutralizing process:

Every cooking oil consists certain amounts of free-fatty acids FFA's that increase the rancidity in oil and is harmful for human consumption. In neutralization, the FFA's are removed by reacting them with caustic soda- NaOH in the neutralizer at a certain temperature and performing the stirring. In this way, FFA gets separated in the form of soap stock. Henan Doing Company offers neutralization units.

Bleaching Process:

The color pigments in the oil are removed in the bleaching process of continuous palm kernel oil refinery plant. The neutralized oil is treated with certain chemicals like activated earth which removes the color from the cooking oil. This process is also carried out under temperature. The bleached oil is then filtered so that the added chemicals and particles are separated from the oil.

Deodorizing Process:

The deodorization is an important process in the continuous palm kernel oil refinery plant. This process is used to remove the odor from the oil. Every oil contains certain typical natural color.

During the previous processes, certain unwanted odor is applied on the oils. The deodorization process removes this odiferous material. It is carried out under high temperature and vacuum systems. At the completion of the process, we get the deodorized-odorless cooking oil.

Photos of 50tpd palm kernel oil refinery plant :

Continuous palm kernel oil refinery plant

Call us

Call us Chat online

Chat online