Crude palm oil production process

Our company is specialized in palm oil mill with 1-2-3-5-10-15-30-45-60-120tph. We have small, medium and large palm oil mill.

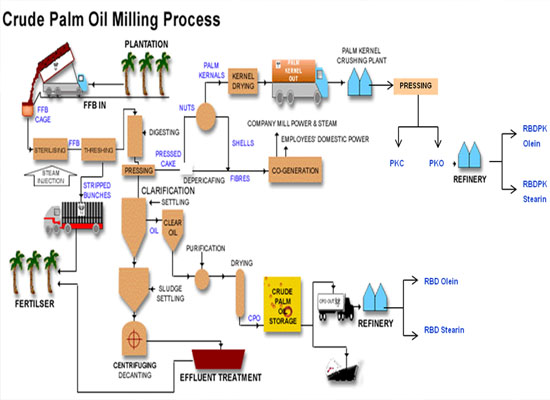

Crude Palm Oil Mill Process Introduction:

crude palm oil process flow chart

1.Weighing.Palm fruit into the factory after truck weighing,ease of production costing and after the settlement.

2.Loading ramp.FFB after a ramp sieved to remove impurities into the transport machinery delivery to sterilization tank.

Palm fruit bunches reception

Horizontal type sterilizing tank

Threshing machine

Empty palm fruit bunches

Digesting tank

Pressing machine

9.Shell and nut.Adopt the ripple mill to crack the nut, after cracking , most of the shell and kernel will be separated by cracked mixture separating system, and the rest of mixture of kernel & shell enter to the special clay bath separating system to separate them, after this processing , we could get pure kernel(The shell content in kernel <6%),which should be conveyed to the kernel silo to dry.After dried moisture as 7%, the kernel will be conveyed to kernel storage bin for storage; Usually the dry kernel’s capacity ratio is 4% . So it should be collected until enough quantity, and then be sent to the palm kernel oil mill; For the separated shell, it should be conveyed to shell temporary bin as the spare boiler fuel.

10.Oil clarification.After screen and sand trap tank, the palm oil should be sent to crude oil tank and heat , then be pumped continuous clarification tank to separate the purified oil which be sent to pure oil tank and the sludge oil which be sent to sludge tank .

Oil clarification

12.Water Treatment.Generally introduced from a nearby river,water throught settling, filtration, dosing and other processes to ensure that the water quality, but also to ensure oil quality.

13.Power system.Power is use of steam power generation turbine generator and also equipped with diesel generators.

Crude palm oil standard:

FFA :≦ 5 %

Moisture :≦0.1 %

Dirt:≦0.02 %

Please have free to contact me if you need our palm oil mill, palm oil processing machine. I can try my best to help you.