Crude palm oil refining process

After palm oil pressing process or palm oil extract process, we get crude palm oil. However, the crude palm oil can’t eat and sell to the market. The crude palm oil must be processed with palm oil refining equipment .

Palm oil refining equipment is through take off impurity, degumming, decoloring, deodorization, removeing wax, fractionation etc, to achieve different standards edible oil. It is suitable for refining various crude vegetable oil, such as sunflower seed oil, tea seed oil, groundnut oil, cottonseed oil, palm oil, rice bran oil, soybean oil, corn oil and palm oil, etc.

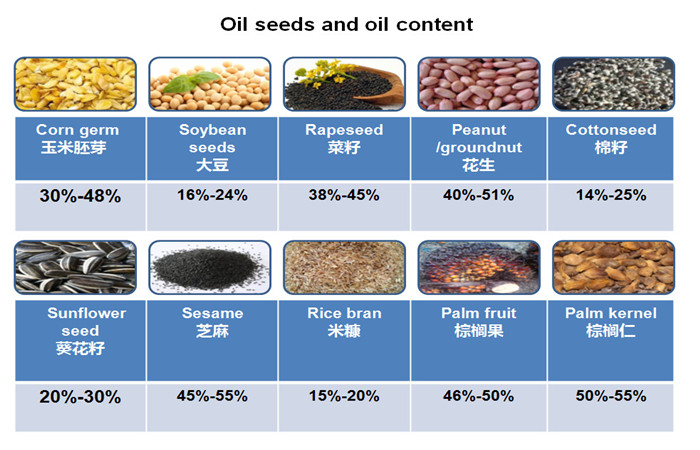

Oil seeds and oil content

1.Neutralizing Section

First stage of refining is to remove Free Fatty Acids (F.F.A.) with caustic soda treatment called Neutralizing Process, thereafter further processed in the bleaching section under vacuum & treated with bleaching earth & activated carbon for removing colour. Finally it will be deodorized under high vacuum and high temperature to remove the odour from the oil.

2.Bleaching Section

The Oil received from previous stages contains traces of soap, iron and few ppm of Phospholipids and Carotenes. These contents are undesirable and required to be removed in Bleaching Operation, Doing's Steam Agitated Bleacher comprises of an acid treatment, a separate Oil and Earth Mixing Device with Mechanical Mixer (this arrangement ensures no carryover of bleaching earth into vacuum system), main bleaching vessel and Hermetic Filters.

3.Deodorizing Section.

Physical Refining process is used to remove FFA (Free Fatty Acid), using Steam Distillation method at high temperature and under high vacuum and it is followed by Deodorization and an extra technical facility is added before deodorisation for removal of free fatty acid.

Deodorization process is used to remove unacceptable odour by Steam Distillation, the Odoriferous Compound are strip off with the help of live injected steam into heated oil under high vacuum.

Palm oil refining machine