60-100 tons FFB/h palm oil milling machine

Palm oil is extracted from fresh fruit bunches (FFB) by a mechanical process, whereby a mill commonly handles 60 to 100 mt per hour of FFB. The palm oil mill of today is based predominantly on concepts developed in the early 1950s (Mongana Report). An average size FFB weighs about 20-30 kg and contains 1500-2000 fruits. The FFBs are harvested according to harvesting cycles and delivered to the mills on the same day. The quality of crude palm oil is dependent on the care taken after harvesting, particularly on the handling of the FFBs.

.

Fresh fruit bunches waitting for processing at palm oil mill

Fresh fruit bunches waitting for processing at palm oil mill

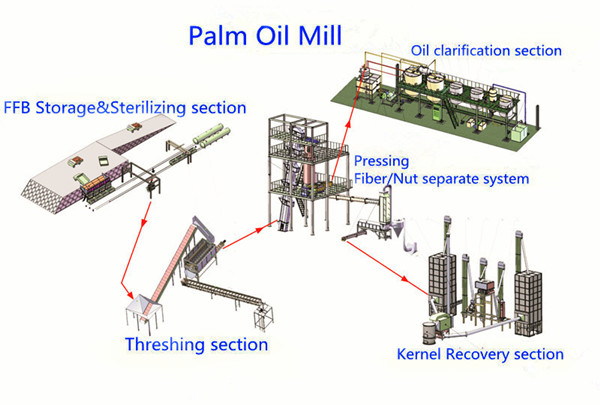

A palm oil mill produces crude palm oil and kernels as primary products and biomass as secondary product. The capacity of mills varies between 60-100 tons FFB/h. A typical mill has many operation units . This comprises sterilization, stripping, digestion and pressing, clarification, purification, drying and storage. For the kernel line, there are steps such as nut/fibre separation, nut conditioning and cracking, cracked mixture separation, and kernel drying, storage. The dried kernels are often sold to palm kernel crushers for extraction of crude palm kernel oil. In some integrated plants, kernel crushing facilities exist side by side at the same complex.

Flow chart for the palm oil mill machine

Sterilization

This first step in the process is crucial to the final oil quality as well as the strippability of fruits. Sterilization inactivates the lipases in the fruits and prevents buildup of free fatty acids (FFA). In addition, steam sterilization of the FFBs facilitates fruits being stripped from the bunches. It also softens the fruit mesocarp for digestion and release of oil, and conditions nuts to minimize kernel breakage. Air is removed from the sterilizer by sweeping in steam in single-peak, double-peak or triple-peak cycles. In general, bunches are cooked using steam at 40 psig in horizontal cylindrical autoclaves for 60-90 minutes. The length of the sterilizer is dependent on the number of cages required for operation of the mill. Each cage can hold 2.5 to 10 tons of FFB. Steam consumption varies from 140 kg/ton FFB for a single-peak cycle to 224 kg/ton FFB for a triple-peak cycle. Inadequate sterilization affects the subsequent milling processing stages adversely.

Palm fruit sterilizer

Vertical sterilizers are also available, which are much cleaner and easier to operate than conventional sterilizers.

Another type of sterilizer technology, the Tilting sterilizer eliminates much of the machinery associated with conventional sterilizers. The technology is the latest design that offers improved milling efficiency, and reduced labour and maintenance cost.

Stripping

Stripping or threshing involves separating the sterilized fruits from the bunch stalks. Sterilized FFBs are fed into a drum stripper and the drum is rotated, causing the fruits to be detached from the bunch. The bunch stalks are removed as they do not contain any oil. It is important to ensure that oil loss in the bunch stalk is kept to a minimum. The stalks are often disposed by incineration, giving ash as potash fertilizer, and fuel for boilers. Others are transported to the plantations for use as fertilisers in mulching near the palms. The total oil loss absorbed on the stalks depends on the sterilizing conditions and partly on the way the stripper is operated. Prolonged sterilization will increase oil loss in stalks. Irregular feeding of the stripper may also result in increase of oil loss in stalks. Stalks which have fruits still attached on them are called hard bunches, and have to be recycled back to sterilizers for further cooking. Hard bunches are detected by visible inspection.

Palm fruit threshing machine also called palm fruit stripping machine

Digestion and Pressing

After stripping, the fruits are moved into a digester where they are reheated to loosen the pericarp. The steam-heated vessels have rotating shafts to which are attached stirring arms. The fruits are rotated about, causing the loosening of the pericarps from the nuts. The digester is kept full and as the digested fruit is drawn out, freshly stripped fruits are brought in. The fruits are passed into a screw press, where the mixture of oil, water, press cake or fibre and nuts are discharged. Improvements in press designs have allowed fruits to undergo single or multiple pressing. Second stage pressing on the press cake fibres enables more oil to be extracted.

Palm fruit digestion and pressing machine

Clarification

A mixture of oil, water, and solids from the bunch fibres is delivered from the palm oil press to a clarification tank. In the conventional process, separation of the oil from the rest of the liquor is achieved by settling tanks based on gravity. The mixture containing the crude oil is diluted with hot water to reduce its viscosity. A vibrating screen helps remove some of the solids. The oil mixture is heated to 85-90°C and allowed to separate in the clarification tank. A settling time of 1-3 h is acceptable. Oil from the top is skimmed off and purified in the centrifuge prior to drying in vacuum dryer. The final crude palm oil is then cooled and stored. The lower layer from the clarification tank is sent to the centrifugal separator where the remaining oil is recovered. The oil is dried in vacuum dryers, cooled and sent to storage tanks.