Palm fruit oil production process

Palm Fruit Oil Production Process:

Palm oil is extracted from fresh fruit bunches (FFB) by mechanical process.The palm oil production process for large scale is complexed. Here we will introduce the process step by step.

Picture: palm fruit bunches

Figure 1. Fresh fruit bunches waiting for processing

The primary products for a palm oil mill is the crude palm oil and kernels. While the secondary products of the palm oil mill is biomass.

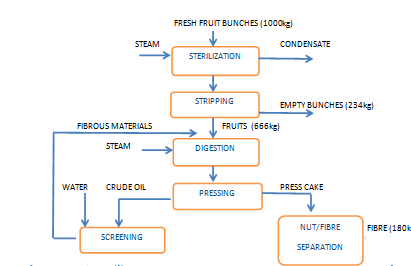

A typical mill has many operation units as shown in Figure 2, for example, sterilization, stripping, digestion and pressing, clarification, purification, drying and so on.

Figure 2. Flow chart for the palm oil process

picture: flowchart of palm oil production process

Sterilisation

This first step in the process is crucial to the final palm oil quality as well as the strippability of fruits. Sterilization inactivates the lipases in the fruits, and prevents build-up of free fatty acids (FFA).

Stripping

Stripping, which is also called threshing, involves separating the sterilized fruits from the bunch stalks. Sterilized FFBs are fed into a drum stripper and the drum is rotated, causing the fruits to be detached from the bunch.

Digestion and Pressing

After stripping, the fruits are moved into a digester. The fruits are reheated to loosen the pericarp in this process. The steam heated vessels have rotating shafts to which are attached stirring arms.

Clarification

The water, solids from the bunch fibres is mixed with oil. In the palm oil production process, the oil is separated from the rest of the liquor by centrifugal.