Small scale palm kernel oil refinery plant

Small scale palm kernel oil refinery plant introduction:

Basing on the traditional oil refining technology, our company has developed the latest palm kernel oil refining technology. Moreover, a series of advanced technology and equipment are used, such as super wet deguming, bleaching earth automatic metering, negative pressure decoloring, high vacuum steam jet deodorization, deacidification, winterization dewaxing etc. With advanced technology, superior equipment, full-automatic control and excellent economic and technical parameters, our small scale palm kernel oil refinery plant can meet customers’ different refining requirements at home and abroad.

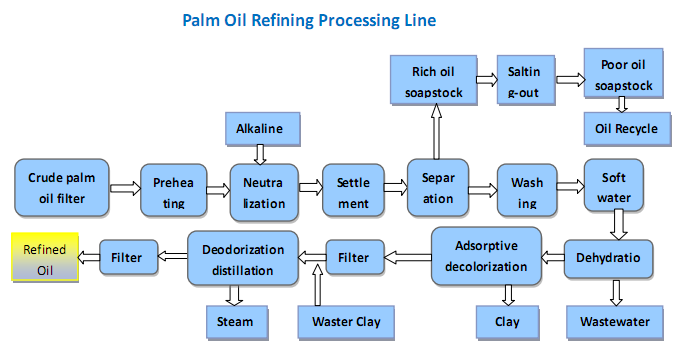

Small scale palm kernel oil refinery flow chart:

Palm oil refining processing line(Palm kernel oil refining process is the same with palm oil refining process)

Small scale palm kernel oil refinery process:

Degumming and Deacidification Section:Palm kernel oil degumming and deacidification section uses washing method to separate soap residual from mixing oil, providing preparation for next step palm kernel oil refinery process.

Decolorizing Section:Palm kernel oil decolorizing section is mainly used to remove oil pigment, residual soap and metal ions during palm oil milling process.

Deodorization Section:Palm kernel oil deodorization section composes of part of crude palm kernel oil mill processing equipment. It plays important part in improving oil quality after crude palm kernel oil process.

Featured advantages of palm kernel oil refining process:

◆Advanced crude palm kernel oil refining equipment configuration and precise equipment manufacturing

◆Automatic control system

◆Excellent technical and economical indicators

◆Meeting customers’ different palm kernel oil refining requirements at home and abroad

◆Palm kernel oil refinery covers entire processing line of degumming and deacidification, blenching, deodorization and fractionation.