Crude palm kernel oil refinery processing machine

Our company is specialized in palm kernel oil refinery processing machine. We can provide the palm kernel oil refinery processing machine from 1 ton to 500 tons. The popular capacity is mini palm kernel oil refinery machine from 1-5 tons, small scale palm oil refinery from 5-20 tons and other palm kernel oil refinery from 20-500 tons. Our equipment suitable for various edible oil refining machine. For example, rice bran oil refining machine, peanut oil refining/refinery machine, soybean oil refining machine, sunflower oil refining machine and so on. Usually the palm kernel oil refinery machine includes three parts: deacidification, decolorization, deodorization and crude palm kernel oil fractionation part.Only in this way,can we get higher quality palm kernel oil. In the process of rice bran oil refinery machine, sunflower oil refinery machine and corn germ oil refinery machine, it needs winterization part to move the wax in the crude oil.

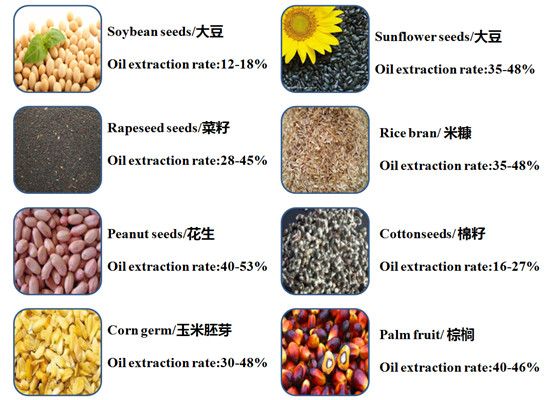

Oil seeds and oil extraction rate

Palm kernel oil refinery production machine is used for removing the harmful impurities in the crude palm kernel oil , it can effectively improve cooking oil quality .Palm kernel oil refinery machine can be used for refining various kinds crude vegetable oil.So,there are more and more customers interest in this production line .

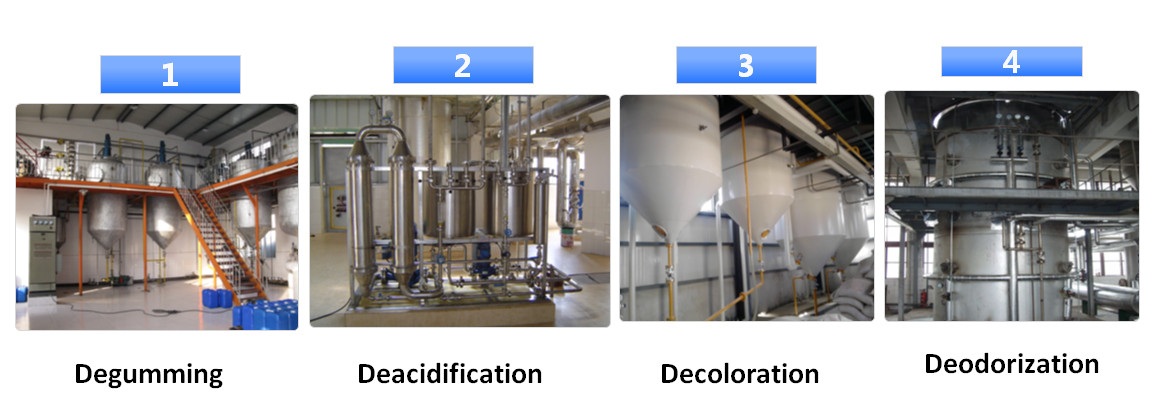

Palm kernel oil refinery machine

A.Degumming section:

This is the most important section of hydrate de-gumming, the water (there is a little P-acid in water) amount, temperature and water adding speed are very important.

B.Deacidification section:

Using alkali like (NaOH) to neutralize FFA in oil, during this process it will produce soapstock , then separating it from the oil. NAOH solution not only neutralize free fatty acid, but also can act with other substances like protein, mucus, phospholipid, pigment. In the batch type and semi-continuous refinery , separating the nigre by sedimentation method . But in the continuous refinery , we usually using the centrifugal to separate the soapstock.

C.Decolorization Section:

Because there is pigment in crude oil, the oil color is dark. In order to improve oil color, we need to using the active clay to absorb the pigment away , then using vibrating filter to separate the waste clay. If you want to get light color oil, you need to add more active clay. Customer can accord to his requirement to control the oil color.

D.Deodorization and Dehydration Section:

General speaking , the crude palm kernel oil smells not good, it will affect of oil storge and selling prices. So we usually use the direct steam to take odors. At the meanwhile, there is about 0.5% water content in refined oil, because the high temperature in the deodorization tower or pot, dehydration section is also finished in this part.

E.Fractionation Section:

Palm kernel oil fractionation goes through the control of palm oil cooling and crystallization to make separation of palm oil into low melting point liquid (soft fat) and high melting solid (stearin). Fractionation of palm kernel oil can be divided into two fractions: stearin (palm stearin), soft fat (palm olein).