Palm kernel oil production line:pressing and refining

Henan Doing Company is professional palm oil production machine manufacturer.We provide complete palm kernel oil production plants and customized service.We are able to offer a range of professionally designed palm kernel oil pressing machine and palm kernel oil refining machine.

Palm kernel oil production line=palm kernel oil pressing production line + palm kernel oil refining production line

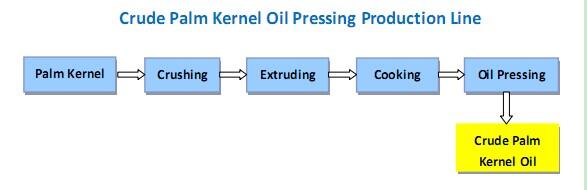

Main process in palm kernel oil pressing production line:

Crude palm kernel oil pressing production line

◆Palm kernel crushing:because the palm kernel is hard and big size, it is required to crash to smaller and even pieces. If once crashing can not reach the requirements, the second crashing is required. Crush palm kernels after softening and drying. The centrifugal crusher breaks nuts and separate palm kernel out completely.

◆ Palm kernel and nuts shell separation. Both dry and wet separations are available. Wet separation is mostly used in palm kernel separation, on basis of difference of relative density of palm kernel and shell.

◆ Palm kernel drying. Fresh kernel contains 20% moisture. Palm kernel has no mildew during transportation and storage while moisture drops below 7%.

◆ Cooking section: It is used for heating and cooking the crashing materials, to make is suitable for pressing, doing like this can help final user get the maximum oil and good quality cakes.

◆ Palm kernel oil pressing. Palm kernel oil pressing processing line is simple with usual oilseeds. The pre-pressing by oil pressing machine can obtain 1/4 palm kernel oil, and residual oil need twice pressing.

◆ Palm kernel Filtering section: after pressing, there are some oil dregs in the crude oil, after clarifying, we need to filter the crude oil to avoid to jam the oil pipes during refining processes.

Palm kernel oil pressing workshop

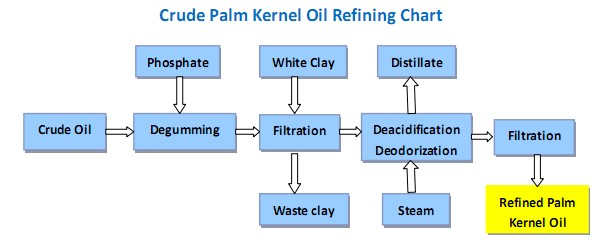

Palm kernel oil refining production line introduction :

Palm kernel oil refining processing line adopts advanced and scientific physical refining and totally stainless steel tank refining. Palm kernel oil is non-drying oil with low gum content, which is suitable for physical refinery. Fatty acid composes of 45%-51% lauric acid and 13%-25% cardamom acid. Palm kernel oil contains soap grade and food grade.

Process Flow chart of palm kernel oil refining plant:

Process Flow chart of palm kernel oil refining plant:

Crude palm kernel oil refining process

Simple introduction of palm kernel oil refining:

◆ Decolorization. Whit clay makes continuously decolorization of crude palm kernel oil, and enters into filter for filtration.

◆ No need of degumming. Physical oil refining is applicable because of low gum content inside palm kernel oil.

◆ High vacuum deacidification. Gas supported heat-conducting oil boiler and packed tower make high vacuum deacidification from crude palm kernel oil.

◆ Fat acid Condensing recovery. Stainless steel recycled water is adopted to make direct condensing recovery of fat acid