-

Palm oil refinery

Palm oil fractionation plant

Palm oil fractionation plant

Palm oil fractionation means to control cooling crystallization process to separate palm oil to 3 parts: palm stearin, palm olien and palm midfraction. -

Palm oil refinery

Palm oil cooling and crystallization eqipment plant

Palm oil cooling and crystallization eqipment plant

Cooling and crystallization are key palm oil fractionation process. Once crystallization successes, palm oil separation becomes easily. Therefore, different type of crystallization should have own cooling exchange surface. -

Palm oil refinery

Palm oil filtration machine

Palm oil filtration machine

Palm Oil Filtration selection is extremely important for improving yield of liquid palm oil during palm oil fractionation process. Currently industrial filtration system contains drum filter,plate frame filter, and vertical leaf filter. -

Palm oil refinery

Palm oil refining degumming and deacidification sec

Palm oil refining degumming and deacidification sec

Washing: there is still about 500ppm soap in the neutralized oil from the separator. To remove the remaining soap, add into the oil about 5~8% hot water, with water temperature 3~5 ℃ higher than the oil generally. -

Palm oil refinery

1-20TPD batch palm oil refinery machine

1-20TPD batch palm oil refinery machine

1-20TPD batch palm oil refinery machine is the main equipment of palm oil processing process. 1-20TPD batch palm oil refinery machine is suitable for small capacity, which contains Degumming, Neutralizing, Decolorization and Deodorization section. -

Palm oil refinery

Dry fractionation of RBD palm oil

Dry fractionation of RBD palm oil

The Henan Doing dry fractionation process is designed to separate palm oil into two fractions, Olein and Stearin.Same palm oil fractionation plant can be used for producing super olein and palm mid fraction of varying cloud point and melting point. -

Palm oil refinery

Palm oil fractionation technology

Palm oil fractionation technology

Palm oil fractionation technology adopts advanced palm oil processing technology of controlled cooling, crystallization, filtration and separation technology, obtaining palm oil with different melting points, like 33℃, 24℃, 18℃, 14 ℃ -

Palm oil refinery

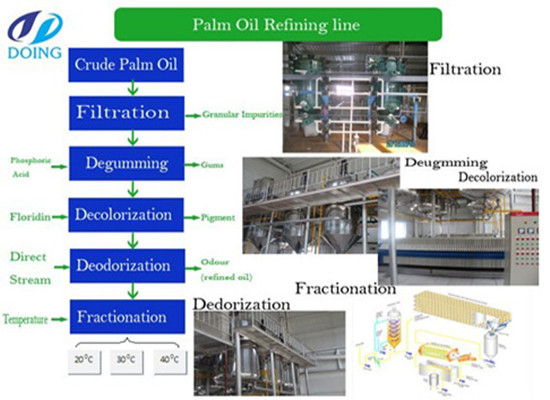

Crude palm oil refining process

Crude palm oil refining process

After palm oil pressing process or palm oil extract process, we get crude palm oil. However, the crude palm oil can’t eat and sell to the market. The crude palm oil must be processed with palm oil refining equipment.