-

Palm oil press

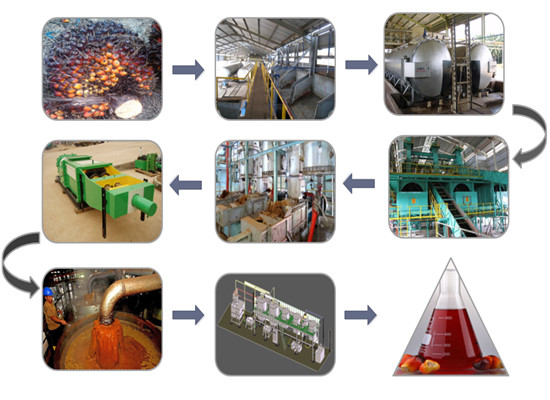

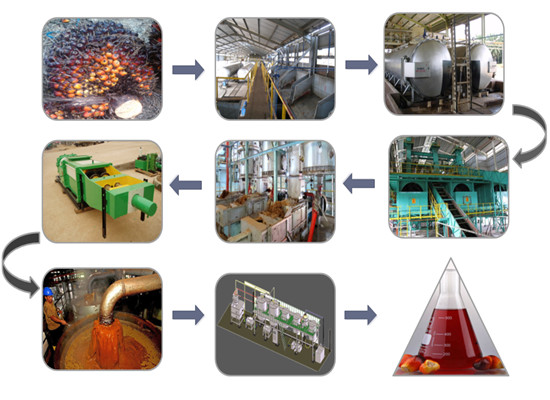

Palm fruit oil production process

Palm fruit oil production process

Palm oil is extracted from fresh fruit bunches (FFB) by mechanical process.The palm oil production process for large scale is complexed. Here we will introduce the process step by step. -

Palm oil press

(FFB) Palm fruit oil processing plant

(FFB) Palm fruit oil processing plant

Technlogy flow chart of palm fruit oil processing plant including:1 .Bunch reception;2.Threshing (removal of fruit from the bunches);3.Sterilization of bunches;4.Digestion of the fruit;5. Pressing (Extracting the palm oil) -

Palm oil press

3-20tph vital breakthrough palm oil mill plant

3-20tph vital breakthrough palm oil mill plant

The palm oil is the world's second largest edible vegetable oil, only ranking after soybean oil. At present, Malaysia and Indonesia is two largest palm oil producing countries in the world. -

Palm oil press

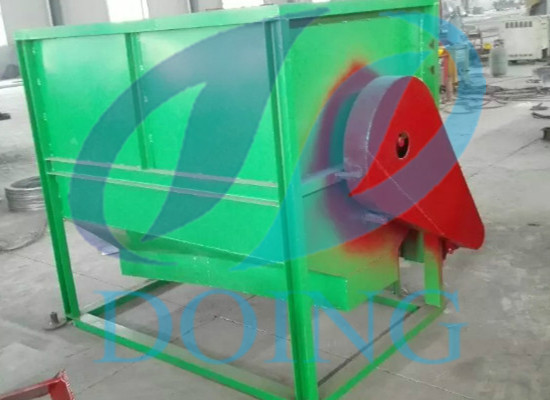

Palm fruit threshing machine

Palm fruit threshing machine

Palm fruit threshing machine uses strong vibration to make separation of palm fruit from palm bunches. Raw materials after sterilization are sent to bucket elevator through damp car, and elevated into threshing machine. -

Palm oil press

Crude palm oil plate filter

Crude palm oil plate filter

In the CPO, it has below non-glyceride components such as trace metals, kernel shell pieces and products of oxidation. So to remove these components and makes the palm oil edible and sellable. The palm oil plate filter is extremely important. -

Palm oil press

Crude palm oil making process

Crude palm oil making process

Because of sterilizing, threshing and crashing made the pulp soft and damage pulp cellstructure, the palm pulp becomes soft and cell is broken. Then it is sent to continuous screw press. -

Palm oil press

Small scale palm oil processing equipment

Small scale palm oil processing equipment

Palm oil is the popular in Africa.,West Africa, Cameroon,Nigeria,Cote d‘Voire,Nigera,Ghana, In order to help all the farmers to make their palm oil, we design a small scale palm oil processing equipment. -

Palm oil press

Small scale palm oil processing equipment

Small scale palm oil processing equipment

Since 1986,as a palm oil production company-DOING GROUP.Our product have passed international ISO9001 quality. Besides, the palm oil processing equipment reached the advanced level in the line. Our products have exported to many other countries in the