Batch type palm kernel oil refinery plant

Batch type palm kernel oil refinery plant is a machinery set up manufactured and developed to refine the crude palm kernel oil with the key step of elimination of impurities from that crude palm kernel oil. We Henan Doing Company offer small scale to medium scale to large scale Palm Kernel Oil Refinery Plants on Turnkey basis. We design and develop complete edible oil refinery plant and system specially for palm kernel oil.

『Related posts: 1-10tpd batch type palm kernel oil refinery plant video 』

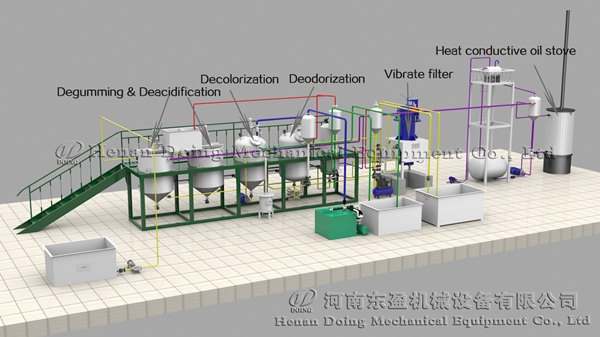

More information about batch type palm kernel oil refinery plant can be obtained by going through the below pictures.

Batch type palm kernel oil refinery plant

Batch type palm kernel oil refinery plant

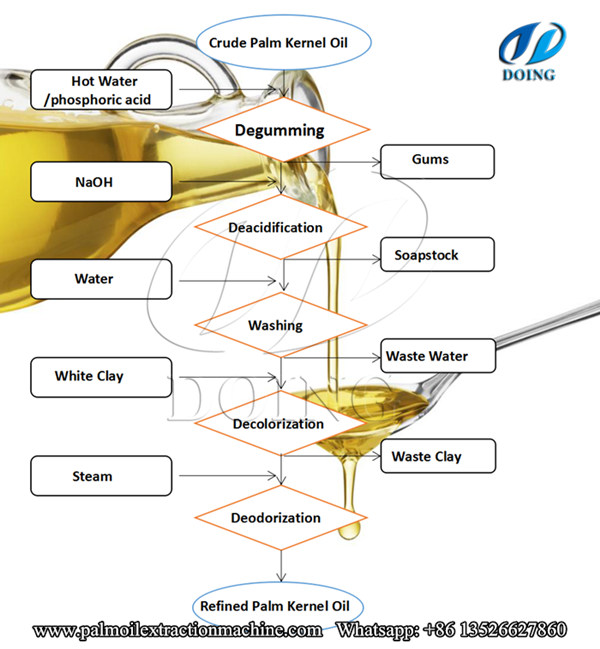

Palm kernel oil refinery process are as follows:

Palm kernel oil refinery process flow chart

Palm kernel oil refinery process flow chart

Our Batch Type Palm Kernel Oil Refinery Plant will give High-Quality Refined palm kernel Oil. The palm kernel oil refining process always including the following sections: degumming, neutralizing, bleaching, deodorizing. In the entire palm kernel oil refining process, a lot of refining equipments can also be used, such as neutralizing pot, degumming pot, bleaching pot, vertical leaf filter press machine, vacuum filter, deodorization pot, FFA catcher, and so on.

Different capacity palm kernel oil refinery plant

Different capacity palm kernel oil refinery plant

Functions of batch type palm kernel oil refinery plant:

Neutralization Reactor (deacidification machine): For acid refining, alkali refining and water washing.

Decolorization Reactor(decolorization machine): To Bleach the Oil and remove pigment from oil.

Deodorization Reactor(deodorization machine): Removes odor from oil.

Thermal Heater: Provides heat energy to raise the temperature.

Vacuum Pump: Provides vacuum degree for decolorization and deodorization.

Air Compressor: Dry decolorization of bleaching clay.

Filtration Unit: Filters bleaching clay and to remove impurities.

Steam Generator: Provides steam for deodorization & distillation.

Batch type palm kernel oil refining process:

1: degumming and deacidification section;

In the degumming and deacidification section of palm kernel oil, soap residue was separated from the mixed oil by water washing, which provided preparation for the next step of palm kernel oil refining process.

2: decolorization section;

Palm kernel oil decolorization process is mainly used to remove pigment, soap residue and metal ions during palm kernel oil production.

3: deodorizing section;

Palm kernel oil deodorization mainly through distillation method to remove the odor in crude palm kernel oil, improve the quality of edible oil.

『Related posts: 5tpd palm kernel oil refinery plant project in Liberia 』

Economic and technical indicators of 1tpd batch type palm kernel oil refinery plant (degumming, deacidification, bleaching, deodorization):

| Project Name | 1tpd palm kernel oil refinery plant |

| Steam consumption: | 0.5bar and 1tph |

| Compressed air: | 6-8bar, 0.8m³/min |

| Cooling water: | you need to build a cooling water pool outside of the workshop with concrete, the cooling water can be recycled and used, 2-4t/d, at normal temperature below 32℃. |

| Phosphoric acid concentration: | 85% food grade |

| NaOH concentration: | solid caustic soda flakes |

Henan Doing Machinery is a company specializing in palm kernel oil refinery plant. We can provide 1-1000tpd palm kernel oil refinery plant . Generally speaking, the processing capacity of batch type palm kernel oil refinery plant is 1-20 tons, that of semi-continuous palm kernel oil refinery plant is 20-50 tons, and that of full-continuous palm kernel oil refinery plant is more than 50 tons. Of course, this is only the reference range, not the final plan. All the friends who choose to cooperate with our Henan Doing company, our engineers will make reasonable plans for you according to your processing capacity and actual production conditions.

prev: Nothing

Call us

Call us Chat online

Chat online