Palm oil refinery plant Manufacturer & Supplier

The palm oil refinery plant can remove harmful factors such as : free fatty acids (FFA), gums, sediments, odoriferous and colouring materials present in crude palm oil to make the oil edible.

Henan Doing Company is a professional manufacturer & supplier of palm oil refinery plant, we can offer batch type palm oil refinery plant and continuous palm oil refinery plant according to the customer's requirements.

Palm oil refinery plant manufacturer

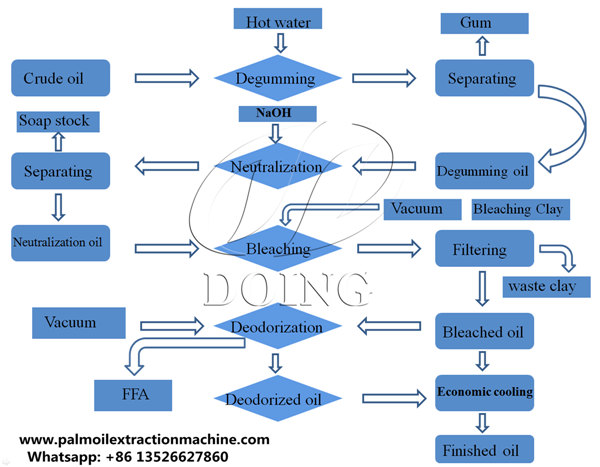

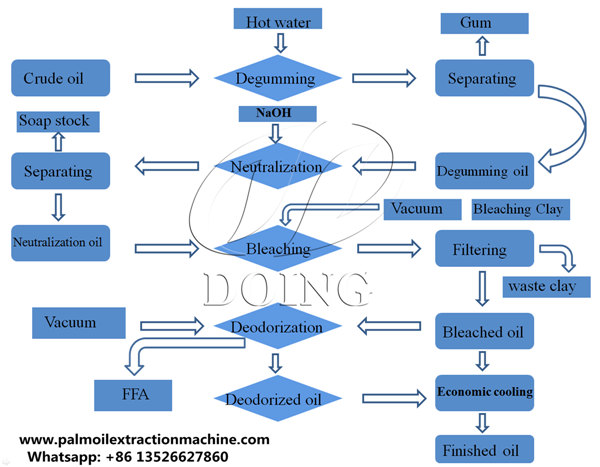

Palm oil refinery process flowchart:

Palm oil refinery process flowchart

The whole palm oil refinery process includes Degumming process, Neutralization process, Bleaching process and Deodorization process. the detail introductionof palm oil refinery processes are as follows:

Degumming / Neutralization

Degumming is a process of removing phospholipids to improve its physical stability and facilitate further palm oil refining.

Phospholipids can lead dark colored oil and they can also serve as precursors of oil off -flavor. Free fatty acids, pigments and other impurities are also partially removed by degumming.

Henan Doing Company follows different type of degumming processes. These processes are being selected based on methods of processing, chemicals used and the content of phosphatides in the crude vegetable oil.

Neutralization: Add the alkali for neutralization, and the alkali quantity and alkali solution concentration depend on the quality of the crude oil. Through the heater, the neutralized oil is heated to the temperature (90℃) suitable for centrifugal separation to remove the phospholipids, FFA and other impurities in the crude oil. Then the oil goes to the washing process.

Bleaching process:

“Bleaching” is a process of selective removal of pigments and impurities by the physical and chemical interaction of an adsorbent with an oil or fat to improve its quality.

This process refers to the art of removing : Color pigments, Dirt, Trace metals, Removal of polycyclic Aromatic compounds, Phospholipids.(Since the bleacing process is carried out under controlled parameters, better and consistent quality of resultant oil is guaranteed.)

Deodorization Process:

Deodorization is a vacuum stripping process in which a given amount of a stripping agent (usually steam) is passed for a given period of time through hot oil at a low pressure. Hence, it is mainly a physical process in which various volatile components are removed. However, since it is usually carried out at high temperature (220 to 250°C), some chemical, thermal effects may take place as well.

To meet every client's requirements, we offer a wide range of palm oil refinery plant of different capacities. We are dedicated to designing, supplying and service all your refinery needs, set up workshops on palm oil refinery plant and turn around your output from 1 to 600 tons a day.

Henan Doing Company is a professional manufacturer & supplier of palm oil refinery plant, we can offer batch type palm oil refinery plant and continuous palm oil refinery plant according to the customer's requirements.

Palm oil refinery plant manufacturer

Palm oil refinery process flowchart:

Palm oil refinery process flowchart

Degumming / Neutralization

Degumming is a process of removing phospholipids to improve its physical stability and facilitate further palm oil refining.

Phospholipids can lead dark colored oil and they can also serve as precursors of oil off -flavor. Free fatty acids, pigments and other impurities are also partially removed by degumming.

Henan Doing Company follows different type of degumming processes. These processes are being selected based on methods of processing, chemicals used and the content of phosphatides in the crude vegetable oil.

Neutralization: Add the alkali for neutralization, and the alkali quantity and alkali solution concentration depend on the quality of the crude oil. Through the heater, the neutralized oil is heated to the temperature (90℃) suitable for centrifugal separation to remove the phospholipids, FFA and other impurities in the crude oil. Then the oil goes to the washing process.

Bleaching process:

“Bleaching” is a process of selective removal of pigments and impurities by the physical and chemical interaction of an adsorbent with an oil or fat to improve its quality.

This process refers to the art of removing : Color pigments, Dirt, Trace metals, Removal of polycyclic Aromatic compounds, Phospholipids.(Since the bleacing process is carried out under controlled parameters, better and consistent quality of resultant oil is guaranteed.)

Deodorization Process:

Deodorization is a vacuum stripping process in which a given amount of a stripping agent (usually steam) is passed for a given period of time through hot oil at a low pressure. Hence, it is mainly a physical process in which various volatile components are removed. However, since it is usually carried out at high temperature (220 to 250°C), some chemical, thermal effects may take place as well.

To meet every client's requirements, we offer a wide range of palm oil refinery plant of different capacities. We are dedicated to designing, supplying and service all your refinery needs, set up workshops on palm oil refinery plant and turn around your output from 1 to 600 tons a day.

Call us

Call us Chat online

Chat online