What is palm kernel oil? How to make palm kernel oil, refined palm kernel oil?

Palm kernel oil (crude palm kernel oil) is expressed from oil palm kernels (Elaeis guineensis L.). However, as a rule, it is obtained by pressing and extraction from the kernels, after which the product is refined (refined palm kernel oil).

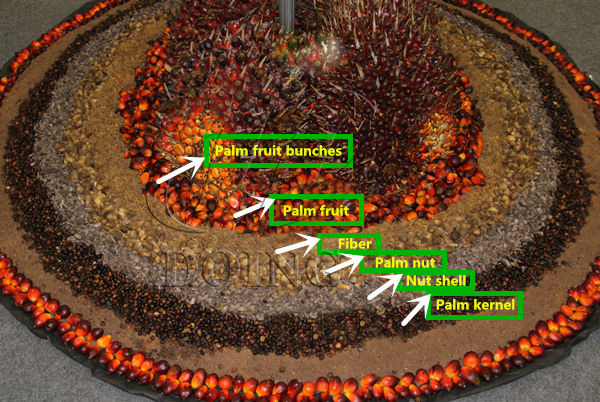

Palm fruit bunches

Palm fruit bunches

↓

Palm kernel

Palm kernel

The oil palm is one of the most important oil-yielding plants. It probably originated in tropical regions, on the eastern side of the Americas and in West Africa.

These plants grow to a height of approx. 20 m and thrive within a temperature range of 24-27°C. They do not fruit for the first 4 years, after which they yield approx. 50 fruits. The main areas in which they are grown nowadays are: West Africa, Indonesia, Malaysia, the Philippines, Brazil and Colombia. Harvesting begins when the fruit starts to fall out of palm fruit bunches. These clusters are then split open with knives. Each palm fruit bunches contains up to 2000 individual pieces of fruit, with a hard core surrounded by soft fruit flesh. Palm kernel oil is obtained from the kernel and palm oil from fruit flesh from which the kernel has been removed.

Crude palm kernel oil and refined palm kernel oil

Crude palm kernel oil and refined palm kernel oil

Unlike the fruit flesh, the seeds (kernels) are extremely hard (making them suitable for storage), which means that oil does not have to be extracted at the place where the crop is harvested. The oil content is 46-53% and oil is obtained - once the product has been dried, pulverised and conditioned - by pressing or flaking and (solvent) extraction. At room temperature, crude palm kernel oil (or fat, depending on the temperature) is solid, yellowish-brownish and has a characteristic smell and taste. Once it has been refined, it becomes a white to yellowish seed oil with a typically neutral, pleasant taste. The oil is highly saturated, with the emphasis on lauric acid (80%), making it fundamentally different from palm oil. It is, in fact, far more akin to coconut oil.

Palm kernel oil is used in the production of margarine and cold-process soaps, also in the cosmetics industry. In the aluminium industry, palm kernel oil is used as a grease during rolling and deep-drawing processes for aluminium sheeting. In the food industry, palm kernel oil is used for baking and cooking.

But do you know how to make palm kernel oil? How to refine palm kernel oil? As palm kernel oil refinery plant manufacturer and supplier, i will tell you the whole palm kernel oil extraction process and whole palm kernel oil refining process.

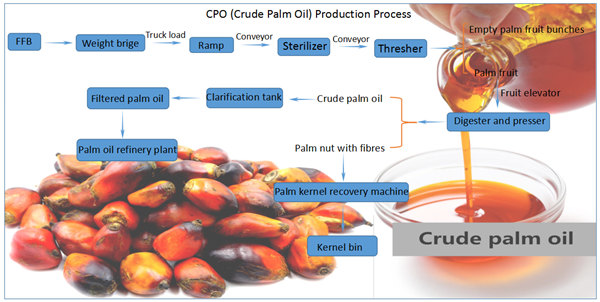

Palm kernel oil extraction process as follows:

Automatic palm kernel oil extraction machine have six parts:cleaning station,crushing station,softening station,flaking station,cooking station,pressing station, filtering station

Palm kernel oil extraction process flow chart:

Palm oil extraction process

Palm oil extraction process

Main process of palm kernel oil extraction machine:

Palm kernel cleaning station: It is used for removing the iron impurities, stone, fiber and pthers. These impurities are bad for automatic palm kernel oil processing plant, especial for the palm kernel oil expeller.

Palm kernel crushing station: because the palm kernel is hard and big size, it is required to crash to smaller and even pieces. If once crashing can not reach the requirements, the second crashing is required.

Palm kernel softening station:Softening adjusts moisture and temperature of oil seeds, softens and increases plasticity of oil seeds. For palm kernel, softenning is an essential process for better flaking effect.

Palm kernel flaking station: Flaking creats beneficial condition for cooking.

Palm kernel cooking station:Cooking is to wet, heat, steam and to cook flakes to change the internal structure of flakes, including destorying cells, protein solidification and denaturation, etc. All these changes makes oil easy to isolate and also enhance crude oil quality.

Palm kernel pressing station: Palm kernel oil press machine is to press oil from oil seeds ,Basically we can get most of the palm kernel oil.

Palm kernel filtering station: After pressing, there are some oil dregs in the crude oil, after clarifying, we need to filter the crude oil to avoid to jam the oil pipes during palm kernel oil refining processes.

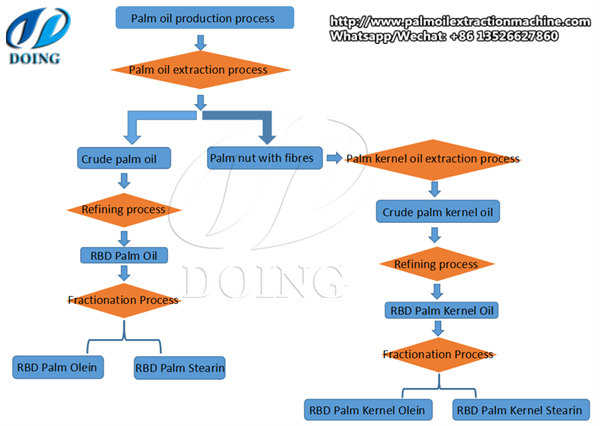

Palm kernel oil refining process as follows:

Palm kernel oil refining machine is used for removing the impurities of palm kernel oil, such as fatty acid, phosphatide, pigment. After the process of palm kernel oil refining machine, the refined oil reaches the edible oil standard.

Palm kernel oil refining process flow chart:

Palm kernel oil refining process

Palm kernel oil refining process

Main process of 2tpd palm kernel oil refining machine:

(1) Degumming ---- to remove gum and impurities from crude oil

(2) Deacidification---using alkali to neutralize acid inside crude oil

(3) Decoloration--- using clay to bleach crude oil

(4) Deodorization-- using deodorizing tower to remove odor from crude oil , then will get refined peanut oil

We can supply palm kernel oil extraction machine, palm kernel oil refining machine , palm kernel oil fractionation plant , if you need our palm kernel oil machine, please feel free to contact us ! You will never let down.

Call us

Call us Chat online

Chat online