Most asked questions about palm oil refinery plant

Why crude palm oil need to be refined?

Before palm oil is made ready for human consumption, crude palm oil need to go through a number of different processes in a palm oil refinery plant. Simply defined, refining is the process of removing impurities which may be present in the cooking oil. Palm Oil refining is a way to get rid of the harmful impurities and needless substance in the crude oil, aims at improving the oil storage stability, flavor and color. Then get standard quality edible oil or provides qualified material for deep processing products.

Small scale palm oil refinery plant

Small scale palm oil refinery plant

Palm oil refinery process flowchart:

crude palm oil → degumming → deacidification → decolorization → deodorization → (winterization/fractionation) → standard palm oil

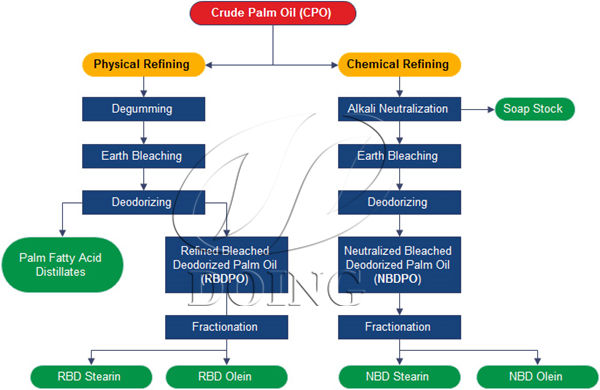

Palm oil refinery process ( physical refining and chemical refining)

Palm oil refinery process ( physical refining and chemical refining)

Different types of palm oil refinery plant :

There are mainly two palm oil refining methods: chemical and physical method. we can devide the palm oil refinery plant into three types according to different capacity: batch type, semi-continuous type refinery, fully-continuous type refinery.

What is the differences batch type palm oil refinery plant, semi-continuous palm oil refinery plant and continuous palm oil refinery plant?

Batch type palm oil refinery plant: the process is to refine the oil batch by batch, suitable for small capacity like 1-2-3-5-10TPD.

Semi-continuous type palm oil refinery plant: degumming, deacidification, decolorization part of the refinery plant is batch type and deodorization part is fully continuous tower. This is cost-effective and labor saving technology, suitable for medium capacity like 10-30TPD.

Continuous type palm oil refinery plant: the whole refinery process is fully continuous, no need much human operating, suitable for bigger capacity above 30TPD.

Photos of different types palm oil refinery plant :

Batch type palm oil refinery plant :

Batch type palm oil refinery plant

Batch type palm oil refinery plant

Semi-continuous palm oil refinery plant :

Semi-continuous palm oil refinery plant

Semi-continuous palm oil refinery plant

Continuous palm oil refinery plant :

Continuous palm oil refinery plant

Continuous palm oil refinery plant

What is the palm oil refinery process?

After palm oil expeller machine or palm oil mill, all the crude palm oil will be delivered to palm oil refinery plant to refine.The whole palm oil refinery process consists of palm oil degumming & deacification process. palm oil decolorization process and palm oil deocorization process.

Deatail introduction of palm oil refinery process as follows:

1. Degumming & deacidification process:

Degumming is using phosphoric acid ,water to react crude oil and then separate phosphatide from oil. But in order to reduce more phosphatide, after enough phosphoric acid treatment, adding alkali inside oil to neutralize free fatty acid , and washing before gum separation , this process is called deacidification. Here the byproduct is soap stock which can be used for making soap.

2. Decolorization process:

Decolorization is using clay to bleach oil , in this step of palm oil refinery process, clay will absorb dark colorant of oil .The quantity of clay is depending on the deepness of crude oil. After bleaching , used clay will be screened out by vibrating screen.

3. Deodorization process:

This step is to remove some unnecessary odors from crude palm oil. Normally for chemical oil refining ,it adopts plate deodorizing tower using high temperature steam to remove odors.

Application of palm oil refinery plant:

Our palm oil refinery plant is widely used in various kinds of crude edible oil refinery process

Our palm oil refinery plant is widely used in various kinds of crude edible oil refinery process

After above steps , the final product is refined palm oil also named RBD Palm Oil,but some cooking oil need more treatment such as dewaxing for sunflower oil, fractionation for palm oil etc.

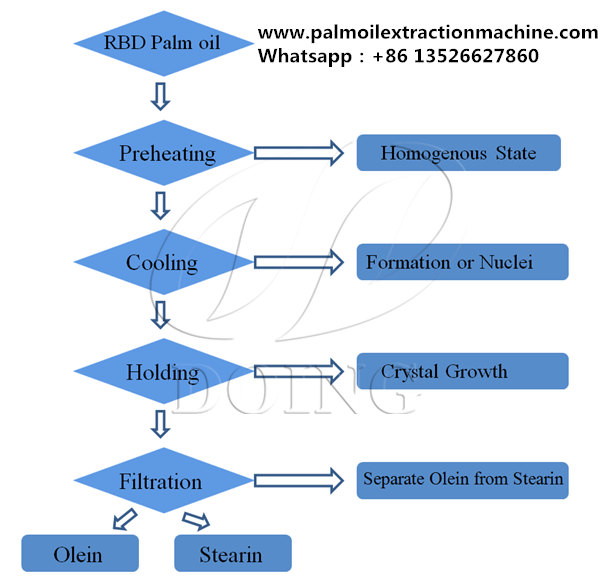

What is palm oil fractionation ?

The palm oil fractionation process is designed to separate palm oil into two fractions, Palm Olein and Palm Stearine without the addition of any chemical or solvent. Henan Doing Company palm oil fractionation plants can be counted upon to produce stable and filterable crystals giving you a product that fits your standard and quality requirements. And crystallization and fractionation is a new concept that has been patented, and it is the best fractionation technology for fat modification for various applications.

1-10tpd palm oil fractionation plant

1-10tpd palm oil fractionation plant

Palm oil fractionation process flow chart

Palm oil fractionation process flow chart

What is the application of palm oil fractionation?

A-Palm Stearine: It is suitable for making margarine and shortening.

B-Palm Olein: Soft fact is excellent frying oil.

Call us

Call us Chat online

Chat online