3 palm oil extraction process about palm oil from plantation

Close your eyes and imagine this: it’s a relaxing Sunday morning, and you’re at your breakfast table. You take a sip of your delicious creamy hot chocolate, and then a bite of your freshly toasted bread with smooth margarine spread. You switch the television on to watch the morning news, and grab a bowl of crispy, savoury fritters to munch on while enjoying your relaxing day off. Sounds good doesn’t it? Food is essential in our lives. In fact, many of us love to eat, especially with our loved ones. Given all the pleasures and nutrition we get from food, have you ever wondered how your daily groceries such as margarine and cooking oil reach your kitchen or dining table?

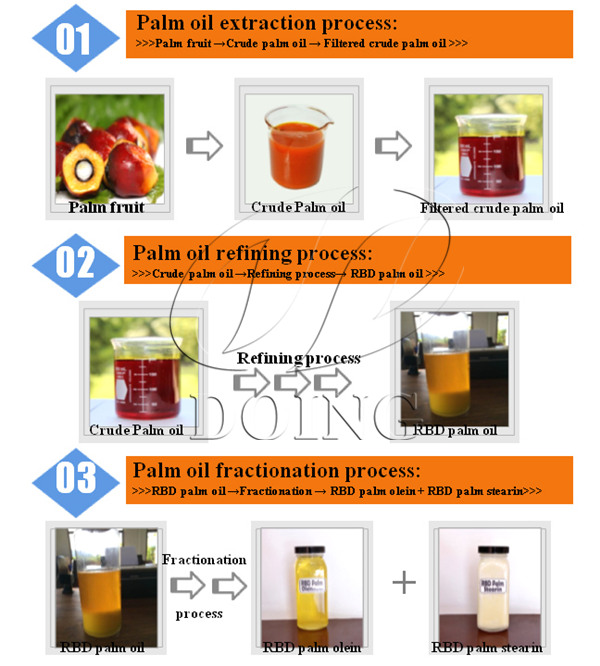

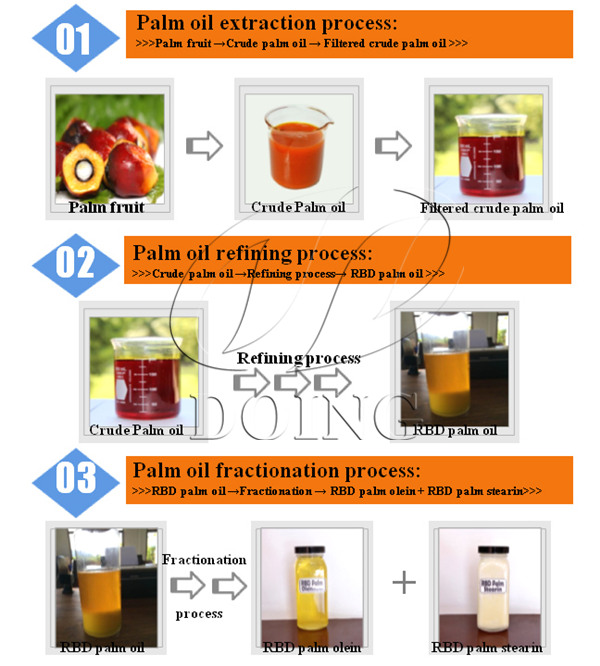

As the main ingredient of margarine, cooking oil, and several other food products, palm oil goes through 3 palm oil production processes ( palm oil extraction process, palm oil refining process and palm oil fractionation process) before reaching the aisles of a supermarket, ready for consumption. Let us take you through the steps of how palm oil reaches your dining table!

Palm oil production process which can produce crude palm oil, RBD palm oil and palm olein, palm stearin

Next you will see the palm oil production process:

The first part—— palm oil extraction process

Basic information of oil palm:

Oil palm belongs to palmaceous plant; It is mainly distributed in tropic area and some sub-tropic areas; It is one of the most important tropic oil seed plants in the world . The oil rate in oil palm is very high: generally 46~50% in the fresh pulp , and 50~55% in palm kernel.And the palm fruit is the raw materials of palm oil production line.

The palm oil is contained in palm pulp, the pulp is high moisture content and rich lipase. Usually we adopt the method of press to produce it, and this palm oil extraction technology is very mature. Complete set palm oil extraction process include a series of process,such as Raw Materials Storage Section,Sterilization Section, Threshing Section,Digesting&Pressing Section,Oil Clarification Section,Palm Kernel Recovery Section and so on.

Palm oil extraction machine (through palm oil extraction process, we can get crude palm oil)

The second part——palm oil refining process

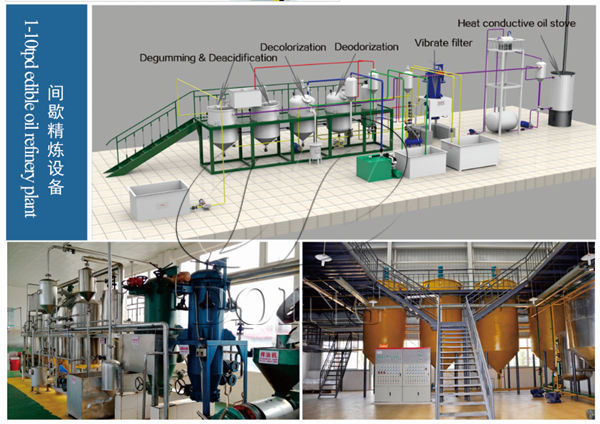

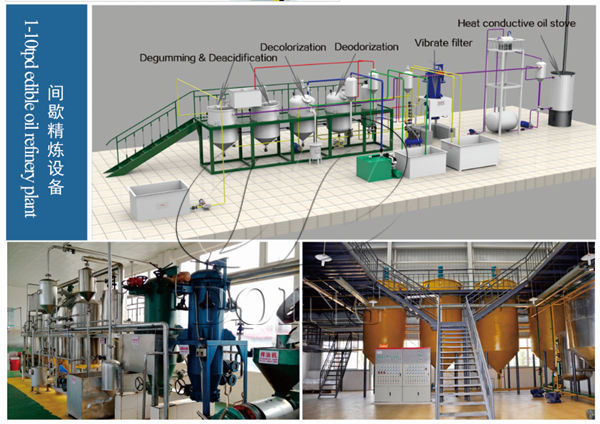

Palm oil refining process is to get rid of the harmful impurities and needless substances in the crude palm oil, aims at improving the oil storage stability, flavor and color. There are mainly four steps of palm oil refinery plant: degumming, deacidification, decolorization, and deodorization .The palm oil refinery plant can be used to process other oil seeds of different capacities as well.

Batch type palm oil refinery plant (through palm oil refinery process we can get rbd palm oil)

The third part—— palm oil fractionation process

Palm oil fractionation technology is a new oil processing technology. Using palm oil fractionation technology can get 8℃,10℃,14℃,18℃,24℃,33℃,44℃,55℃ etc, different melting point's palm oil product. At the same time, it can also be used to do cottonseed oil, fish oil ,pork oil and other animal oils. This prominently improves the added value of the oil products, increase the economic benefit of enterprise.

Palm oil fractionation plant (through palm oil fractionation process we can get palm olein and palm stearin)

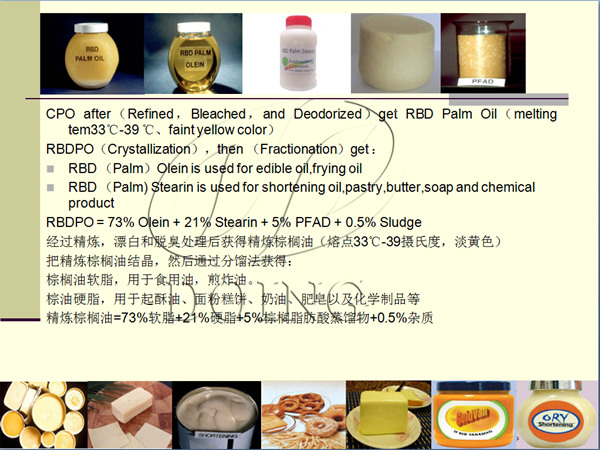

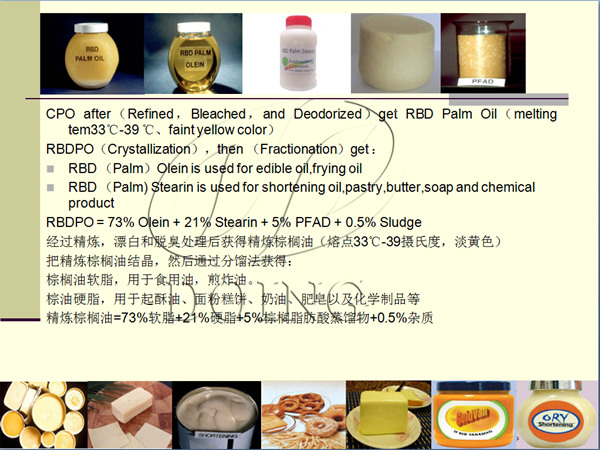

After the above palm oil production machine, we can get different stage palm oil. After palm oil extraction process, we can get crude palm oil, after palm oil refining process, we can get RBD palm oil. After palm oil fractionation process, we can get palm olein and palm stearin. In a word,there are many uses of palm oil and palm kernel oil and the next introduction will be useful for you to better understand the applications of palm oil and palm kernel oil in the global oils and fats industry today.

Palm oil is a kind of plant oil made from palm fruit. It is one of the largest produced, consumed and traded oils in the world, which is called The World’s Three Major Vegetable Oils together with soybean oil and rapeseed oil. Palm oil after pressing, refining and fractionation can get different melting point products, which are widely used in catering industry, food industry and oil & fat industry.

The wide applications of palm oil

Major palm oil applications in food are:

Cooking oil and frying fats.

Margarine and spread.

Shortening.

Sugar confectionary.

Spray dried fats and whipped emulsion.

As the main ingredient of margarine, cooking oil, and several other food products, palm oil goes through 3 palm oil production processes ( palm oil extraction process, palm oil refining process and palm oil fractionation process) before reaching the aisles of a supermarket, ready for consumption. Let us take you through the steps of how palm oil reaches your dining table!

Palm oil production process which can produce crude palm oil, RBD palm oil and palm olein, palm stearin

Next you will see the palm oil production process:

The first part—— palm oil extraction process

Basic information of oil palm:

Oil palm belongs to palmaceous plant; It is mainly distributed in tropic area and some sub-tropic areas; It is one of the most important tropic oil seed plants in the world . The oil rate in oil palm is very high: generally 46~50% in the fresh pulp , and 50~55% in palm kernel.And the palm fruit is the raw materials of palm oil production line.

The palm oil is contained in palm pulp, the pulp is high moisture content and rich lipase. Usually we adopt the method of press to produce it, and this palm oil extraction technology is very mature. Complete set palm oil extraction process include a series of process,such as Raw Materials Storage Section,Sterilization Section, Threshing Section,Digesting&Pressing Section,Oil Clarification Section,Palm Kernel Recovery Section and so on.

Palm oil extraction machine (through palm oil extraction process, we can get crude palm oil)

Palm oil refining process is to get rid of the harmful impurities and needless substances in the crude palm oil, aims at improving the oil storage stability, flavor and color. There are mainly four steps of palm oil refinery plant: degumming, deacidification, decolorization, and deodorization .The palm oil refinery plant can be used to process other oil seeds of different capacities as well.

Batch type palm oil refinery plant (through palm oil refinery process we can get rbd palm oil)

The third part—— palm oil fractionation process

Palm oil fractionation technology is a new oil processing technology. Using palm oil fractionation technology can get 8℃,10℃,14℃,18℃,24℃,33℃,44℃,55℃ etc, different melting point's palm oil product. At the same time, it can also be used to do cottonseed oil, fish oil ,pork oil and other animal oils. This prominently improves the added value of the oil products, increase the economic benefit of enterprise.

Palm oil fractionation plant (through palm oil fractionation process we can get palm olein and palm stearin)

Palm oil is a kind of plant oil made from palm fruit. It is one of the largest produced, consumed and traded oils in the world, which is called The World’s Three Major Vegetable Oils together with soybean oil and rapeseed oil. Palm oil after pressing, refining and fractionation can get different melting point products, which are widely used in catering industry, food industry and oil & fat industry.

The wide applications of palm oil

Major palm oil applications in food are:

Cooking oil and frying fats.

Margarine and spread.

Shortening.

Sugar confectionary.

Spray dried fats and whipped emulsion.

Call us

Call us Chat online

Chat online